Plots

Peygran outdoor support plots are ideal for projects in which a floating, elevated, raised or access floor has to be used.

They are the best alternative to traditional construction methods for this type of project, reducing the weight and removing architectural barriers.

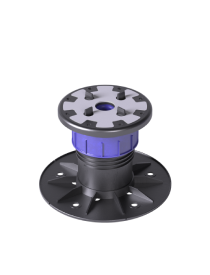

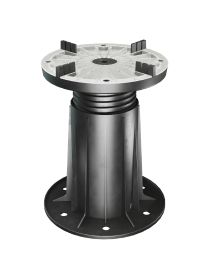

BSP Pedestals

- Adaptable to any situation

- Wide range of heights

- Extendable height

- 4, 3 or 2 mm joint flanges

Easier and safer working with our accessories

Raised Floor Supports

They are the best alternative to traditional construction methods in this type of project, to lighten the weight and avoid architectural barriers. They allow high quality finishes, saving work and facilitating the subsequent maintenance of the installations.

Hidden slopes and drainage

As the tiles are laid on top of the pedestal system, the water passes between the joints and the water drainage system can be installed underneath the paving.

Strong and durable

Our Plots are manufactured with high resistance materials and a design that guarantees a high resistance to loads.

Wide range of heights

Our Plots are available at various heights to ensure installation in any location.

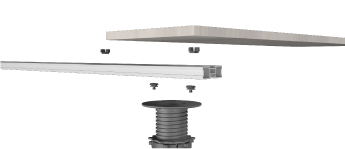

Installation with joist

We have the necessary accessories for installing with battens (both wood and aluminum). Install tiles or even wood flooring (we recommend our NFC Flooring).

Easier and self levelling

We have the necessary accessoires in the pose with cups (wood and aluminum). Possess the carrelage or même of the parquet (we recommend notre reversing the NFC sun).

Made from 100% recycled plastic

Developed together with medical professionals and physiotherapists

Adjustable scale for a perfect fit

The Peygran Ergonomic Pliers for Levelling System minimises the fatigue and injuries caused by muscular overexertion during tiling and flooring work. Creating perfect finishes with less time and effort.

Prevents the problems caused by bending the wrists by aligning the rotation and push axes with the arm axes.

Do you have any further questions?

Please do not hesitate to contact us if you need further information or clarification on any issue.

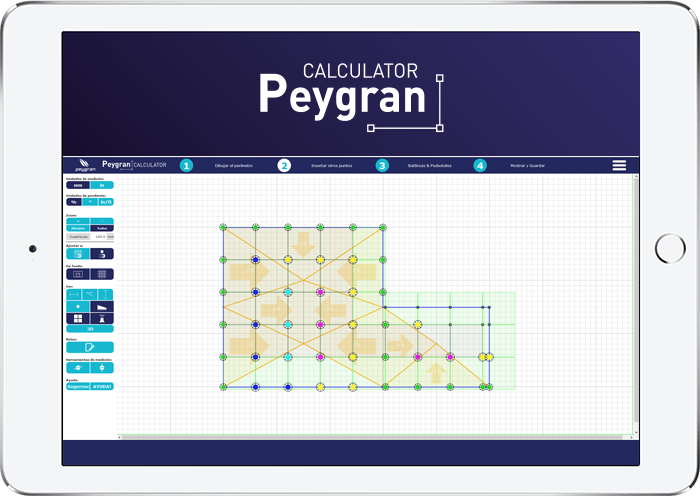

Instrucciones

- 1. Indicar el largo A y ancho B de embaldosado en m

- 2. Indicar el formato de baldosa en cm

- 3. Indicar la longitud máxima entre apoyos que admite la baldosa.

- 4. Indicar si se precisa plot central o no.

TERRAZA

[m²]

BALDOSA

PARÁMETROS DE PLOTS

Longitud máxima

entre Plots [cm]

Plot central

[sí / no]

Junta

[mm]

TOTAL PLOTS

RATIO

uds/m²

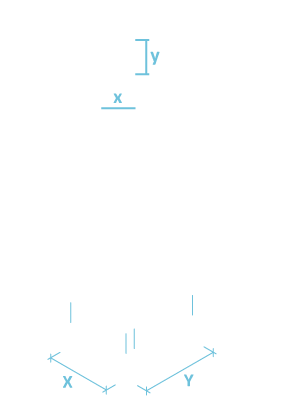

- 1. Indicate the length A and width B of tiling in m

- 2. Indicate the tile format in cm

- 3. Indicate the spacing between joists x, and the distance between plots y. Both multiples of the tile

Plots

Plots Rastrel 2m

Rastrel 2m Ref. 03040141Z

Clip Rastrel

Clip RastrelRef. 03040132E - 100uds.

Cruceta Rastrel

Cruceta RastrelRef. 03040131E - 100uds.

Subscribe to our newsletter< wpml_linebreak > and don't miss a thing

Find out first-hand about all our news, events and new training courses.